Researching the Pros and Cons of Pellet 3D Printer for A Smoother Printing

Nowadays, 3D printers can work directly with resin pellets. It offers material flexibility but necessitates a deeper understanding of optimal ways to process each resin.

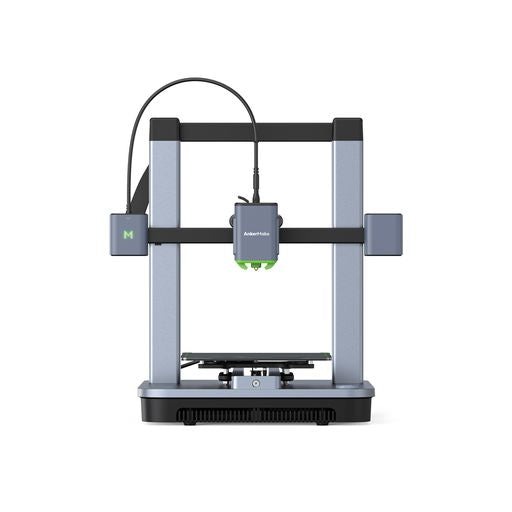

Pellet 3D printing, or FGF (Fused Granular Fabrication) technology, is gaining popularity in industrial manufacturing. Direct printing using plastic granules has several benefits over traditional FDM technology. It is the only production method that is economically viable for some projects.

It is Evo 3D, and in this article, we will discuss pellet 3D printing technology and its benefits.

How Does Pellet 3D Printing Work?

The same material extrusion technology used in FDM 3D printing is also used in pellet printing. The thermoplastic used to make building parts is different, and as a result, a unique extruder made to process plastic granules rather than FDM filament is needed.

Considerations for A Smooth FGF Printing Process

For the FGF or large build volume 3D printer, for the printing process to be reliable and consistent, several important process variables need to be kept under control. Among them are:

• The shape and size of the pellets affect how the material enters and moves through the system.

• Ensuring the material fed into the extrusion unit has the appropriate moisture content.

• Regulating the print heads and extruder's successive heating zones to provide a steady and secure material flow.

• Adjusting screw speed dynamically and adaptively to get the right deposition rate.

• Utilizing a precise motion control system to keep accuracy even at high grandstand traverse speeds.

• Extruder output should be precisely timed with a print head motion to guarantee uniform deposition bead size and shape.

Pros and Cons of Pellet 3D Printing

Let us summarize the advantages and drawbacks of FDM 3D printing comparable to pellet additive manufacturing.

Pros

Reduced material cost: As previously indicated, pellets typically cost a small portion of what identical plastic filament costs.

Faster print speeds: The larger heating zones and wider nozzle diameters of the pellet extruder design of FGF printers allow for significantly higher throughput and faster print speeds. It is useful for batch production and industrial manufacturing of large parts.

Broad choice of materials: In addition to a range of thermoplastic pellets from various producers on the market, users can design unique materials with predetermined characteristics and print using recycled plastic.

Environmental friendliness: FGF 3D printing lowers carbon emissions and plastic waste, creating a safer atmosphere.

Cons

Lower print resolution: It is preferable to use alternative 3D printing technologies when producing miniature models with various fine details and tight tolerances.

Design restrictions: Support structures are rarely utilized in pellet printing because they are challenging to erect and remove. Therefore, FDM machines work better for printing parts with intricate geometries, overhangs, and cavities.

Reduced flow control: Although pellet extruders can process material at a faster rate than filament machines, they are not as capable of controlling the flow. While filament extruders retract the material when moving to a new location, the design of a pellet extruder prevents retraction, which could lead to material leakage.

In Conclusion

When considering industrial printing, FGF technology presents numerous advantages over traditional FDM manufacturing. Production is done on a large scale and in batches becomes far more cost and time-efficient. Pellet 3D printing offers a large selection of pellets and can print with customized and recycled materials; it is a promising technology that will undoubtedly find use in various industries.

For pellet 3D printers or large build volume 3D printers, you can get it at Evo 3D, as they provide a wide range of 3D printers.

Comments

Post a Comment