Industrial FDM Printers: Four Types for Diverse Applications

Printing is a technology people use in different ways in offices, factories, etc. However, the revolution came when 3D printing came into existence. The history of 3D printing started in the 80s when Dr. Hideo Kodama invented a layer-by-layer protocol for printing objects using materials polymerized by UV light.

Now, the technology of 3D printing has come a long way in terms of technology and its usage. Every industry is getting advantages from its existence, and one of the most used is industrial FDM printers. So, let us decode the working and types of FDM printers.

Understanding the Coordinate Systems

Everyone knows about the coordinate axis for dimensions. So, a printer is a machine that operates with specific measurements to work accurately. The industrial 3d printer or others like large build volume 3d printer operates on the exact measurement of axis, length, and width to create an object. Therefore, understanding the concept is essential.

There are three axis, namely X, Y, and Z. This axis indicates the position and location of points in space. These are reference lines or imaginary points to specify the locations. In two dimensions, the X-axis and Y-axis represent the space. However, in three dimensions, the Z-axis is also included, perpendicular to both other axes.

Four Types of Industrial FDM Printer

There are usually four types of FDM 3D printers that people are not aware of. So, here are the types in detail:

Cartesian 3D Printer:

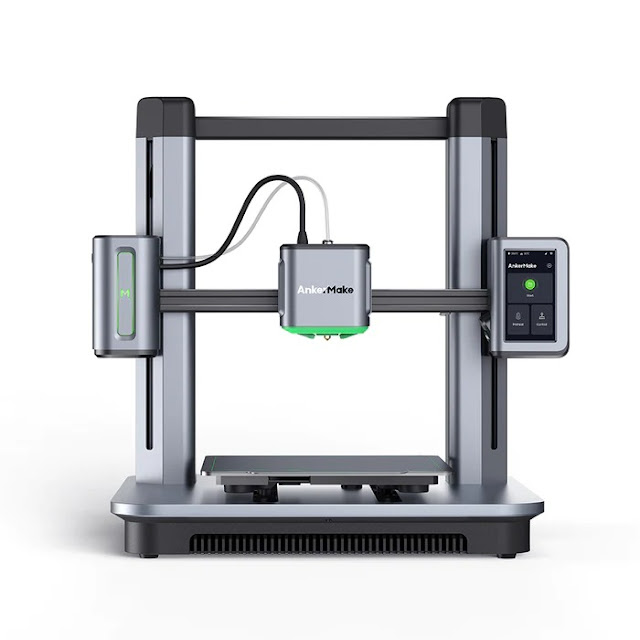

The most famous printer that is most often used in various industries is the Cartesian printer. Also, most people know about this one type, but there are three other types of FDM printers. Apart from being efficient, it is convenient as people can easily get its service and tutorials.

The machine works on the three-axis system where X and Y indicate the lateral and longitudinal positions, and Z shows the escalation at a point.

Polar 3D Printers:

These printers use two aspects to print an object. One is an angle in 3D space and a radius from a defined centre. Polar 3D printers work on circular grids, unlike Cartesian which works on square grids. The build platform of these printers can move effectively, making taller objects in less space. These printers are convenient for building large objects like columns in architectural models.

Delta 3D Printer:

After the Cartesian, it is the second most popular and used industrial FDM printer. They have a tall and unique structure, which looks fascinating to watch during the printing process. There are three arms of the printer that work simultaneously, and due to this, it works in a triangular configuration giving a cylindrical shape to the object. One of the USPs of this printer is its high speed of printing.

SCARA 3D Printers:

SCARA, known as Selective Compliance Assembly Robot Arm provides the best flexibility while printing. There are no restrictions as it moves in all directions, making it possible to complex geometrical shapes. Such printers are usually used in the construction of structures like buildings, bridges, or other industrial projects.

Conclusion

The 3D printers are coming into the limelight due to the huge production and convenience they offer. In addition, they are transforming every industry along with themselves. However, when one is selecting one for themselves, there are various factors that one must consider.

The biggest determining factors are budget and specifications. So, you must see the features you want your printer to have spent on the objects you need to create. The second step is to check if the printer is within your budget.

Comments

Post a Comment