Tips to Choose a Large Format FDM Printer for Businesses

FDM 3D printing is revolutionising the business/production industry. It can cut production time that would otherwise take longer than expected. Many businesses leverage FDM printing in product development applications. Since they are suitable for detailed functional prototypes like durable manufacturing and low-volume manufacturing. This technology is quite suited for detailed functional prototypes, manufacturing tools and low-volume manufacturing. FDM printing is used in the aerospace, medical, consumer goods and automotive industry.

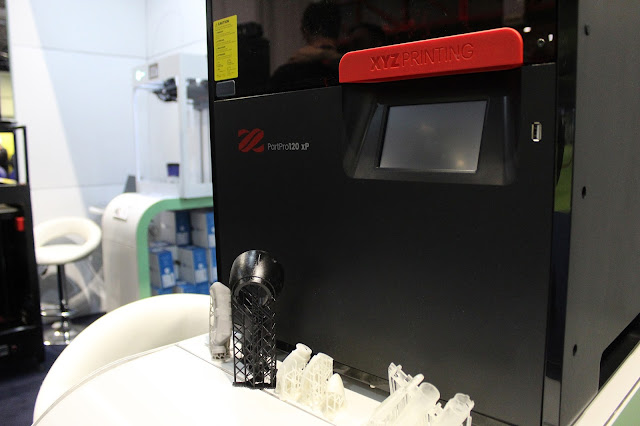

The FDM-produced parts are suitable for detailed functional prototypes, detail-oriented functional prototypes and durable manufacturing tools and low-volume manufacturing. Fused deposition modelling is a printing technology developed by Stratasys. It functions by melting filament to form layers and extruding it onto a printing bed with the help of a nozzle. This filament is usually a plastic or composite-like polylactic acid(PLA).

The FDM Printing Process

Fused deposition modelling (FDM) is an extrusion-based technology which uses building materials like thermoplastic polymers in a filament form. In FDM printing, a part is selected and then melted layer by layer with a CAD model. Due to its high accuracy, low cost and large material selection, FDM is one of the widely used technology right now.

When you explore 3D printing technology, you will get to understand its benefits. A 3D model file contains essential information like how an object is “cut” into layers and creates a code that asks the printer how to create files and creates a code. This method is user -a friendly and affordable method until now that creates a new object instantly. So, let’s know how this works, a 3D model file contains information on how an object is “cut” into layers to create files and creates a code that tells the printer what to do. The FDM 3d printer then creates layers to create one by one to create an object.

Choosing an FDM printer helps you get customised printing solutions of your choice. The FDM 3D printer allows you to go layer-by-layer with depositing melted material You can go layer-by-layer with depositing melted material in a predetermined way. You can get the materials in the form of filaments that comes out of thermoplastic polymers.

FDM Printing Benefits

Only by investing a few minutes or a few hours, you can shorten your lead times and speed up the prototyping process. FDM printers can easily scale out designs like a low-cost-size ratio with an easy low cost -to -size ratio design. Even if you have flexibility with a number of choices in colours. However, some common filament materials you need are acrylonitrile butadiene styrene(ABS), polyethene terephthalate glycol(PETG), polylactic acid(PLA), and Nylon. Here are a few things to consider when choosing a large-format FDM printer.

How To Choose The Best 3D FDM Printer?

1. Quality - When it comes to finishing an important task, you cannot compromise on the quality of these printers. If you want good results and do not want to get into a situation that gets out of your hand, you should go with a reliable system or a product with the highest quality.

2. Features - There are many options out there when deciding on features you need in your 3D printer. There are a variety of features to look for in your printers like bed levelling, connectivity, user interface, motion systems, extruder category and others. Prioritise these things that you want in your system and choose some other that you need later.

3. Size - Choose a printer’s size according to your budget because both are extremely relative. Large printers are great for managing volume. But they are at the same time responsible for poor quality prints due to shaking. Always consider the space a printer is going to take to avoid wasting money and time.

4. Price - Price is another factor to consider when it comes to purchasing a 3D printer. There is a significant range out there to choose from, however, you can look for other considerations before selecting the price you are ready to spend.

In Conclusion,

3D printing produces parts with great precision and utmost finishing. FDM printing can create a fine model. All you need to do is find the right partner and easily get the service as easy as online shopping!

Choose a reliable 3D printing company that offers a range of printers and services and offers other products at a reasonable price too.

Comments

Post a Comment